Aluminum Engraving & Etching

Inscribe Australia has a wide range of aluminum products available for engraving including anodised colour aluminum sheets & natural raw sheets available in different thickness for laser etching and traditional cnc engraving.

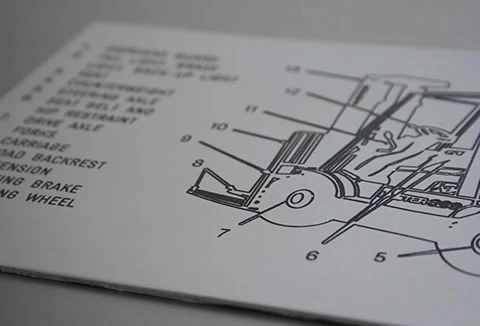

Aluminum is very versatile and can be used on so many applications.We can laser etch, laser cut, cnc-mill, machine engrave and digital print this allows us to create fantastic original looking products. It’s great in any environment it’s also light weight and easy to bend. Aluminum engraving is very popular process for industrial applications such as compliance plates, badges, face plates, name plates, control panels, signage, machine parts and many more. We have years of experience using aluminum and we love working with aluminum!

Read More

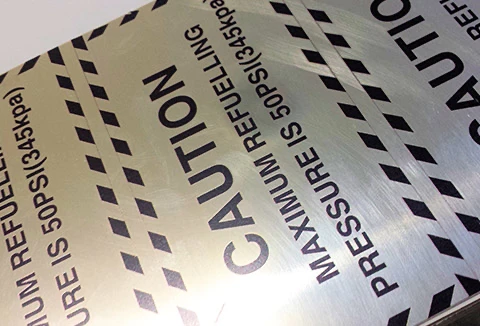

Laser Marking on Aluminum

Anodised aluminum comes in a variety of colors and is engraved with a CO2 laser. Black and dark colour anodised aluminum turns white when lasered. Red and lighter colours are a lighter version of the colour example red produces a very light pink color when lasered. The laser mark is permanent and will not wash or come of with an chemical and is UV Stable. LASER MARKING LEAVES A PERMANENT MARK GREAT FOR SECURITY!

We can laser mark anodised aluminum objects leaving brilliant white or grey finish depending on the colour of the anodising. This mark is super durable and permanent mark. Below is a sample of one the services we provided for school security to there IT devices like IPad’s or notebooks. It’s a great anti theft deterrent and we can even put a barcode or your logo on it.

WHAT IS ANODISING?

Anodising is an electro chemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to Anodising, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

The anodic oxide structure originates from the aluminum substrate and is composed entirely of aluminum oxide. This aluminum oxide is not applied to the surface like paint or plating, but is fully integrated with the underlying aluminum substrate, so it cannot chip or peel. It has a highly ordered, porous structure that allows for secondary processes such as coloring and sealing. Anodising is accomplished by immersing the aluminum into an acid electrolyte bath and passing an electric current through the medium. A cathode is mounted to the inside of the anodizing tank; the aluminum acts as an anode, so that oxygen ions are released from the electrolyte to combine with the aluminum atoms at the surface of the part being anodized. Anodizing is, therefore, a matter of highly controlled oxidation-the enhancement of a naturally occurring phenomenon.

TESTIMONIAL

I was amazed at the detail of the laser etching on aluminum my ipad never looked so cool. I love it! Great job guys.

Samantha

IT Student RMIT

SHORT VIDEO : HOW IS IT DONE ?

SPRAY, SHAKE AND BAKE! TRADITIONAL ENGRAVING WITH SUPER TOUGH POWDER COAT COLOUR FILL

What makes our traditional engraved plates, labels and engraved signs better, eco-friendly and tougher then our opposition?

Well we spray, shake and bake!… We fill all our traditional engraved plates with Dulux Dura Colour Powder coating and bake in an oven at 200 degrees.

Less wastage then paint and a reusable method allow this process to be cleaner and greener process then paint filling.

Read More

Well it’s not that easy but it’s not rocket science! We have a patent process and a secret adhesion to make sure our colours stay bright reducing colour fading, stay in with out flaking and last a lifetime. Years of research and development lead to this innovative out of the box thinking almost every other engraver in the industry uses paint.We think that doesn’t cut It any more not when you want the plate to last for a very long time with low maintenance. It’s also a piece of mind knowing the colours will stay not flake off and can be placed in almost any environment.

With a range of colours to choose from and our team will help you get the best match.